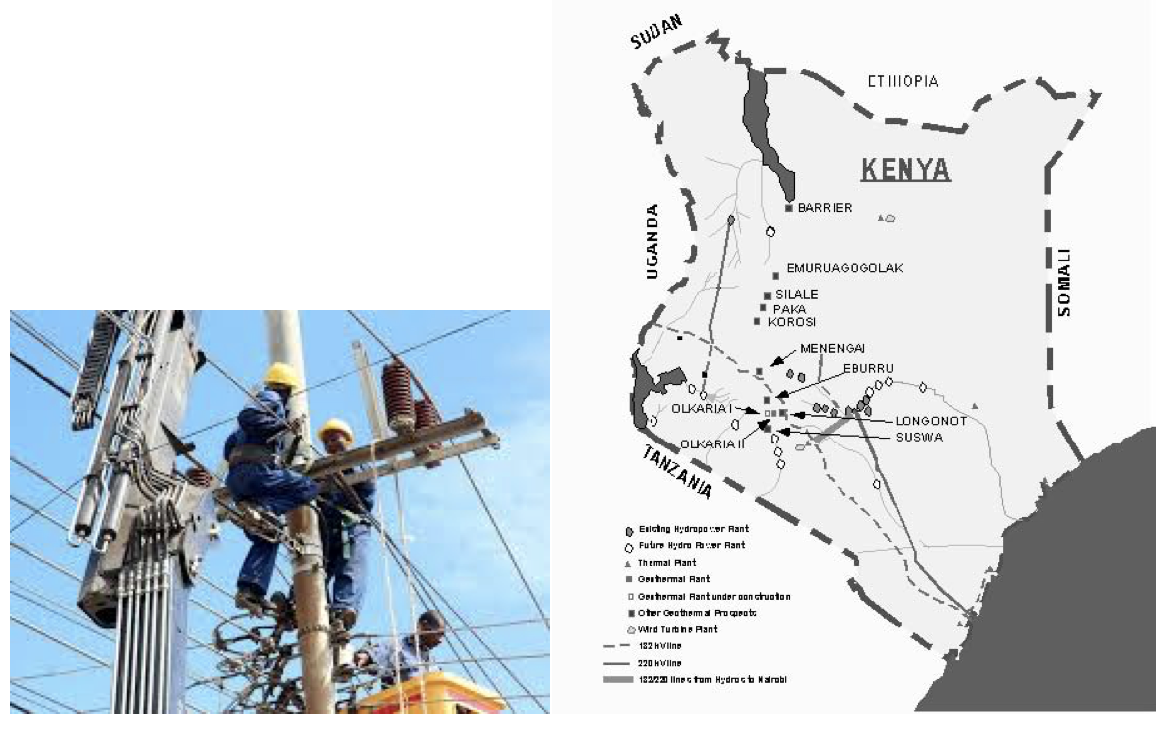

| Owner: Kenya Power Transmission System | Market: Utilities | Services Provided: |

| Project Completion: 2012 | Project Size:

6 km |

Kenya, Africa

Our assignment in this project ($37.5M), serving as consulting field electrical engineers, was to support the operation’s team for design, planning, execution, trouble-shooting electrical components systems, and to train and develop the local field engineers with the same skill set of the GE field engineer team in completing the project’s goals. One of our first tasks was to re-size various equipment with voltage classifications 500/220/132/11kv such as oil circuit breakers, SF6 circuit breakers, Switchgear (SWGR), transformers (1 to 10 MVA), motor controls center (MCC’s), emergency generators power systems, and UPS. We also had to repair the picking correct system and equipment grounded cable.

In the Isinya sub-stations, we had to test and troubleshoot protective relays supporting the station and find the potential fault. And we had to partner with local field engineers from KETRACO to repair the KPTSIP expansion project at Sangoro and Sondu Miriu power stations with voltage classifications of 132 kV at about 5.5km in length. During that assignment, we trained field engineers on gathering data to preform power system studies, to inspect various cables and equipment, and to identify the essential elements needed for record-keeping on various equipment. We used the CYME 5.0 / CYMDIST / CYMTCC / CYMGRD / CYMCAP power tool to perform various utility calculations: voltage drop, power flow, fault flow, short circuit, harmonics, AC contingency, transient stability, dynamic motor starting, arc flash hazard, switching optimization, protective device coordination, and substation grounding, power cable ampacity on distribution and transmission systems. At the conclusion of the study, we explained the principles required to create arch flash labels, how to identify fault scenarios, the system limitations, and relay settings/testing at that location. Other tasks were to provide maintenance support on an outage at the electrical power high voltage distribution and transmission systems sub-stations at Malindi Garsen. This included working on transformers, oil circuit breakers, switchgear motors, motor control centers, lightning, and grounding systems. We had to verify electrical conductor wiring, cable damages, transformers excessively burning oil, the resolution of any FS6 linkage and hazardous area classification. At the conclusion of our mission, the field engineers were much better trained and equipped, and understood more thoroughly their roles as field engineers on a technical and safety level. Because of our involvement, the KETRACO team initiated an employee yearly training plan of action to trigger the occurrence of an incident, and formal record-keeping as part of their yearly goals and vision.